Crankshaft Machinig / Long Shaft Machining

Global crankshaft / long shaft solutions to answer all your needs,

from anywhere in the world.

One of the best domestic technical skills and know-how that we have learned of micron order

It is one of the few independent companies in Japan that has the equipment and technology to carry out integrated production of mass-produced products and high-mix low-volume crankshafts from material to completion.

The crankshafts we manufacture are used in a wide range of industries, including automobiles, motorcycles, outboard motors, light airplanes, agricultural machinery, and industrial machinery.

With the technology and expertise cultivated in this diverse achievement, I gained confidence that I canrespond accurately to every shaft needs.

Please use Micron quality realized by Yuasa for your products.

From the backup of the medium-term crankshaft production system to short-term response, As a strategicpartner to support the development of our customers, we will play a part in suppliers that realize highquality products.

We can also process long shafts used in various industries with the technology we have cultivated over the years in crankshafts.

We can handle the entire process from material arrangement to completion and delivery, including heat treatment and surface treatment.

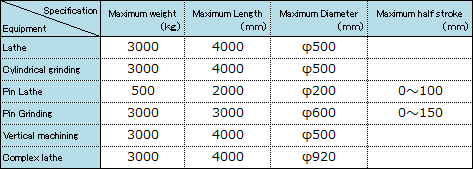

We have abundant equipment required for processing, and we realize high-precision processing with the skills of experienced craftsmen.

Have you encountered these issues recently?

Successor problem / technology inheritance

Aging equipment and employees

Improvement of management efficiency and selection of products handled, etc.

Please leave it to Yuasa with confidence! Start with a free quote!

With abundant equipment, you can start production of crankshafts of any specifications in a short period of time. 45 lathes, 47 machining centers, 64 grinding machines, 9 pin millers, 4 pin lathes, 5 induction hardening machines, etc.

With 170 employees (as of September 2021), we can produce from mass production to small quantity products 24 hours a day.

The manufacturing, production engineering, and inspection departments are independent, and each has a quality check function.

Sales staff are stationed in Tokyo, Osaka, and Okayama. Not only business trip visits but also meetings on various web conferencing systems are welcome.

Application examples

Crankshaft

- Cars

- Trucks

- Buses

- Motorcycles

- Airclafts

- Ships

- General purpose diesel engines

- Agricultural machines

- Pumps

- Generators

- Compressors

- Various industrial machines

- etc.

Long shaft

- Industrial machines

- Construction machines

- Steel manufacurings

- Plants

- Printing machines

- Rotary presses

- Injection molding machines

- Press machines

- Pumps

- Compressors

- Food machineries

- Cutting machines

- Packing machines

- Crushers

- Nailing machines

- Stirrers

- Foil stamping machines

- Automatic flatbed punching machines

- etc.

Quality Control

Thorough quality control has made it possible to produce from small lots to mass production.

Quality control technology crystallized by Yuasa's know-how achieves millimicron accuracy.