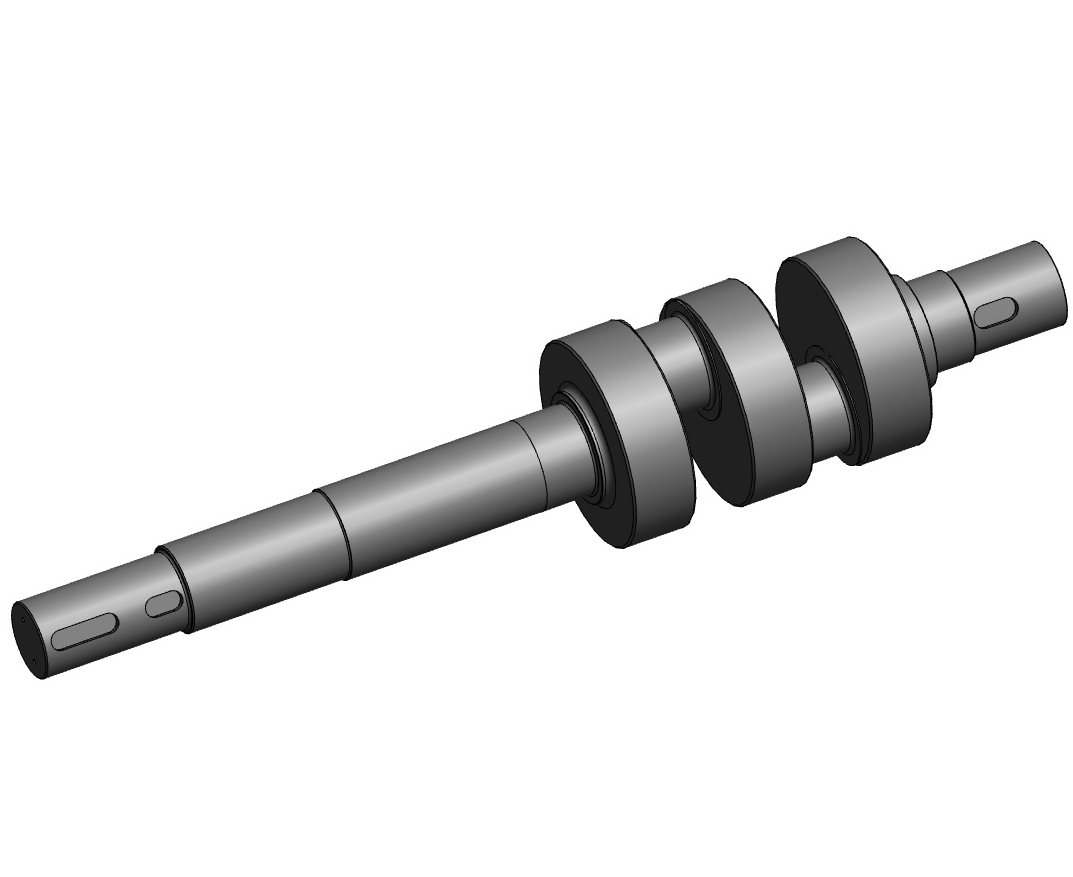

Long Shaft Machining

Utilizing our crankshaft processing technology,

we can machining a variety of long shafts.

- Features and Strengths of Yuasa.

- Processing capacity

- We can also process long shafts used in various industries with the technology we have cultivated over the years in crankshafts. We can handle the entire process from material arrangement to completion and delivery, including heat treatment and surface treatment.

- We have the equipment to process shafts up to 4,000mm in length, and our abundant processing equipment and experienced staff can achieve higher precision with their advanced technical capabilities.

- Proposal capability

- When outsourcing, we design the most suitable process for our processing equipment. We will consider cost reduction by VE proposal from the process design stage.

- We offer various consultations based on our crankshaft processing know-how, such as high-frequency quenching to increase strength.

- Delivery time

- We will provide you with a standard lead time at the time of quotation, but we can also consult with you to shorten the delivery time according to your development schedule and product assembly schedule.

- Production capacity

- We can flexibly handle production from a single unit to dozens of units per month for prototypes and auxiliary parts.

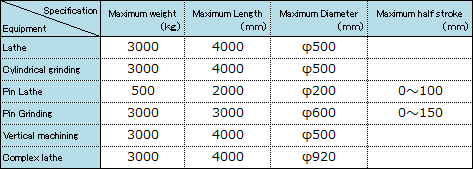

- Processing equipment

- NC lathe

We have three NC lathes that can handle up to 3~4 meters in length.

- Multi-tasking machine

It is a processing facility with multiple capabilities, lathe, machining, and milling. Available up to 4 meters.

- Pin Grinding

This equipment is used for grinding eccentric parts of crankshafts. Available up to 3 meters.

We are capable of machining shafts up to 4,000 mm in length and 600 mm in diameter.

Please feel free to inquire about the possibility of machining your product.

- Quality Control

We utilize our quality control know-how cultivated through the processing of precision crankshafts.

- Material

Rolled steels for general structure(SS)・Carbon steel(SC)・Alloy Steel(SCM)・Stainless steel(SUS)・Steel pipe for structural purposes(STK) etc.

- Heat treatment and surface treatment (many cooperating manufacturers)

Tempering, induction hardening, nitriding, carburizing and quenching, hard chrome plating, etc.

- Machining sample

- SCM435 Round bar φ 78 × 923L

Tempering - SCM440 Round bar φ295 × 1,519L

Tempering, Eccentricity amount

61.5mm - SCM440 round bar φ320 × 716.5L

Tempering Eccentricity amount

14.57mm

Crankshaft ・ Eccentric shaft・ Drive shaft ・ Vibrating shaft ・ Balancer shaft ・ Main shaft ・ Roll ・ Rotor shaft ・ Fan shaft ・ Tie bar shaft ・ Spline shaft ・ Long, medium, and large shaft machining, etc.

- Application example

Industrial machinery, Construction machinery, Steel manufacturing, Plants, Printing machines, Rotary presses,Injection molding machines, Presses, Pumps, Compressors, Food machinery, Cutting machines, Packing machines,Crushers, nailers, Stirrers, Foil stamping machines, Automatic flatbed punching machines, etc.