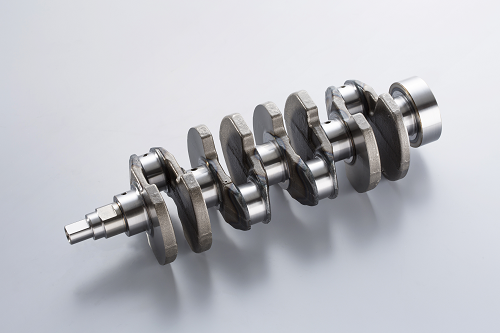

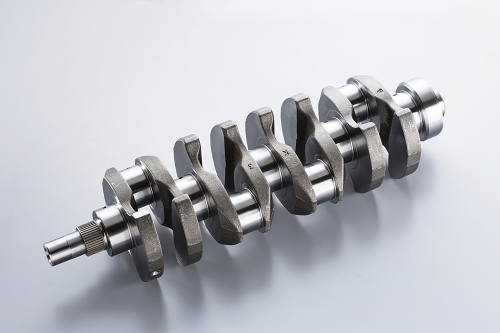

Mass-production Crankshaft

YUASA's mass-production crankshaft line can handle

both small and large lots.

We can also handle large lot production of crankshafts.

Outsourcing reduces costs and increases production efficiency without having excessive equipment in thecompany.

In YUASA's mass production line, after forging materials are fed in, lathing, machining, quenching, grinding,and balance correction

The mass-production line at YUASA is capable of integrated production. We can guarantee a stable supply ofmass-produced crankshafts at the level of several hundred to several thousand units per month.

- Mass-production crankshaft machining by YUASA Features and Strengths

Safely outsource to us

Leave it to YUASA to supply supplies when production efficiency is low due to agingof your equipment or after production is finished. We complete the entire processin-house, so you can outsource with confidence.

- Mass-products(repeated products)

- Small-lot spot production

Please use this product for short-term processing support.

We provide backup so that you wont't lose any orders. We offer processing supportin the short term to cover you during peak production periods, or for when yourproduction capacity cannot keep up with an unexpected increase in orders.

- Production assistance during the "busy" season.

- Help in alleviating back-orders.

Processing support for only partial processing is also available.

When a part of the machine in the production line has a problem and cannot berestored immediately, and it takes time to arrange parts and repair, we process onlythe process that has the problem.

- Immediate response when production is over capacity.

- Backup in times of equipment trouble.

- Seven reasons why you can trust Yuasa.

- We can start production of crankshafts with any specifications in a short period of time with our abundant facilities.

- We can design processes based on our extensive knowledge of crankshaft processing distortion and dynamic balance.

- The introduction of a gun-dry loader enables 24-hour unmanned production line, which results in stable supply and cost reduction.

- Various labor-saving machines are specially designed to prevent unevenness in manual work, work errors, and process skipping due to worker skill level.

- Small parts are delivered as assemblies, so customers can start assembly immediately.

- Traceability can be managed using QR codes, etc.

- Daily delivery according to the customer's assembly schedule is also available.

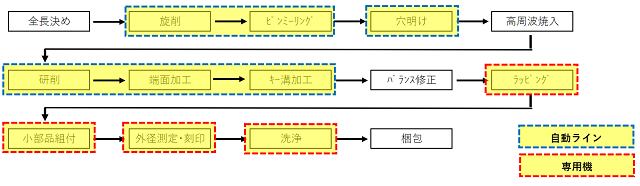

- An example of a machining process using automatic lines and specialized machines.

*The production equipment is set according to the specifications and number of units of the requested model, so it does not necessarily mean that an automatic line or dedicated machine will be manufactured.

- Processing equipment

Facility line

This line conducts crankshaft measurement, journal grinding, and pin milling. Our main Okayama Plant features 5 lines and the shinshiro Plant has 1 line

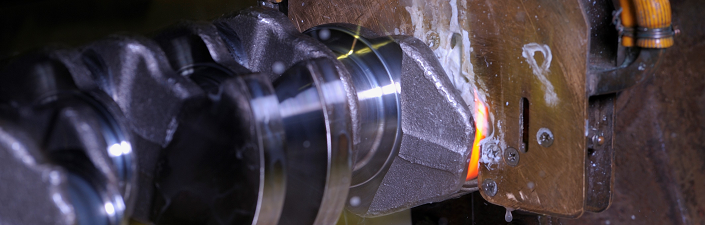

Automated grinding line

This is a fully-automated production line that uses a gantry loader to automate the loading and unloading processes, and also features a journals, pins and bilateral shaft grinding.

Induction hardening equipment

Japan's only induction hardening equipment capable of processing split pins. With this single unit, we can conduct hardening for the crankshaft pin, journal, and bilateral shafts.

Finishing and weapping machine

This machine conducts the polishing for journals and pins the main components of the crankshaft. This device is able to polish all required locations at once.

Ring gear shrink fit equipment

Outer diameter measuring and rank stamping equipment.

Key and knock press fitting equipment

Automatic cleaning equipment